Rolling mill with guide devices arranged in the roll stand near the rolls US3258953A en 1964-02-18. Whether it is appropriate to select have a decisive impact to the productivity and output of rolling mills quality consumption index and production process operation so the selection of rolling mill pass design system must be strictly carried out in accordance with.

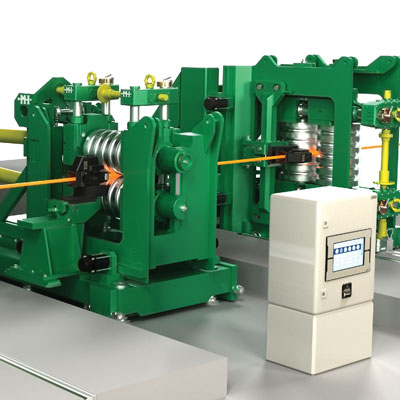

Hot Rolling Mill Manufacturer In India Manufacturing Iron And Steel Industry Design Management

The quality of our guide products are world famous for its.

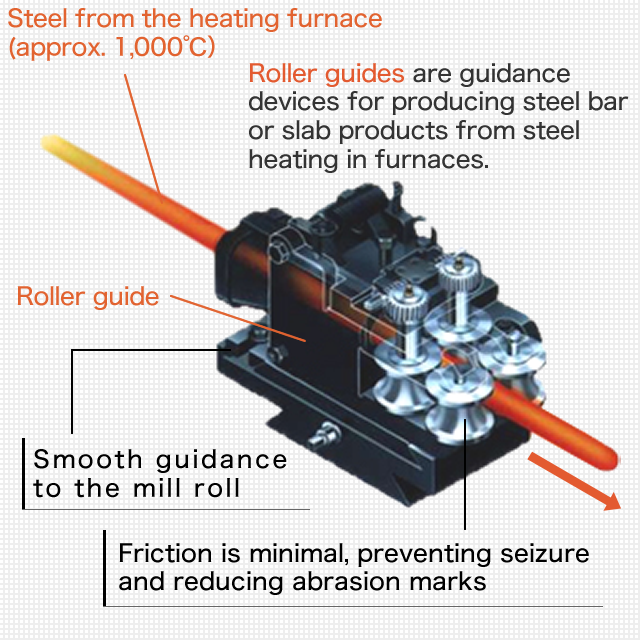

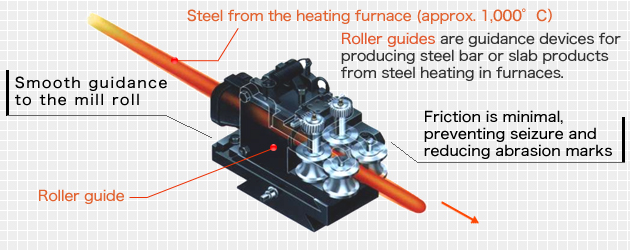

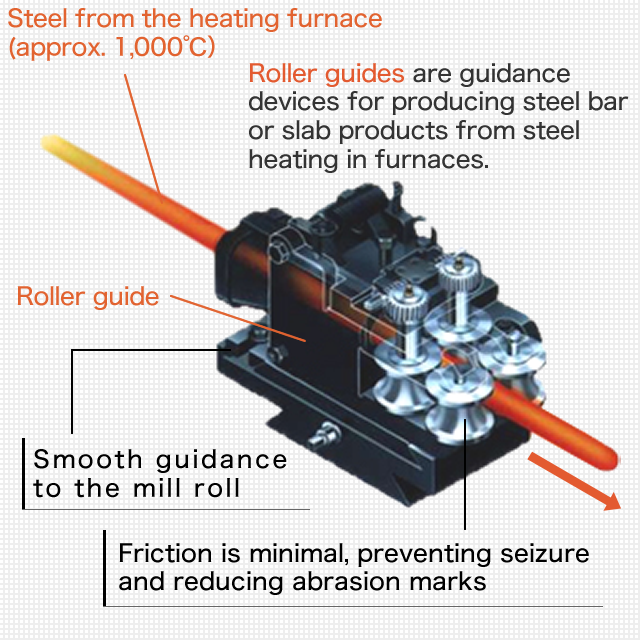

. Roller guide box finds applications in continuous rolling operations in which the stock that is being rolled is properly twisted between each two adjacent rollers in rolling mills. Mill guides also could increase the strength of surface of billet. See more ideas about rolling mill jewelry techniques jewelry making.

It is a combination of software and hardware design concept. After the cross-section has been finalized and before the rolls can be designed the proper number of passes and rolling mill must be determined. Since introducing a revolutionary roller guide product in 1945 we have been leading the international steel industry and introducing a number of patented products for rolling mill systems.

Rolling Mill Stands. Incorporate fixtures guides side rolls and straightening devices where applicable. Oct 1 2018 - Explore Navanites board Rolling Mill Patterns Designs on Pinterest.

It is full compliance with industrial standard quality. Mill guides could clear oxide scale of billet and make the surface of billet more smooth. Passes are designed to meet the requirements.

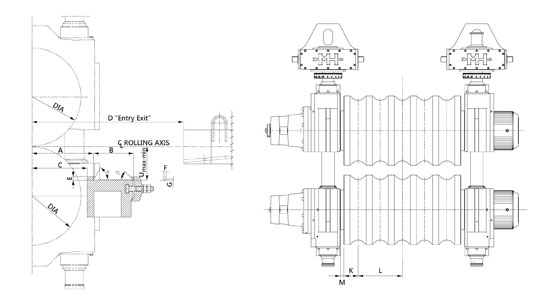

A roller guide for rolling mills which comprises two pivot pins arranged symmetrically with. Roll body roll diameter and roll head. The construction of the stripper guide can of course be modified in design or replaced within the scope of this invention.

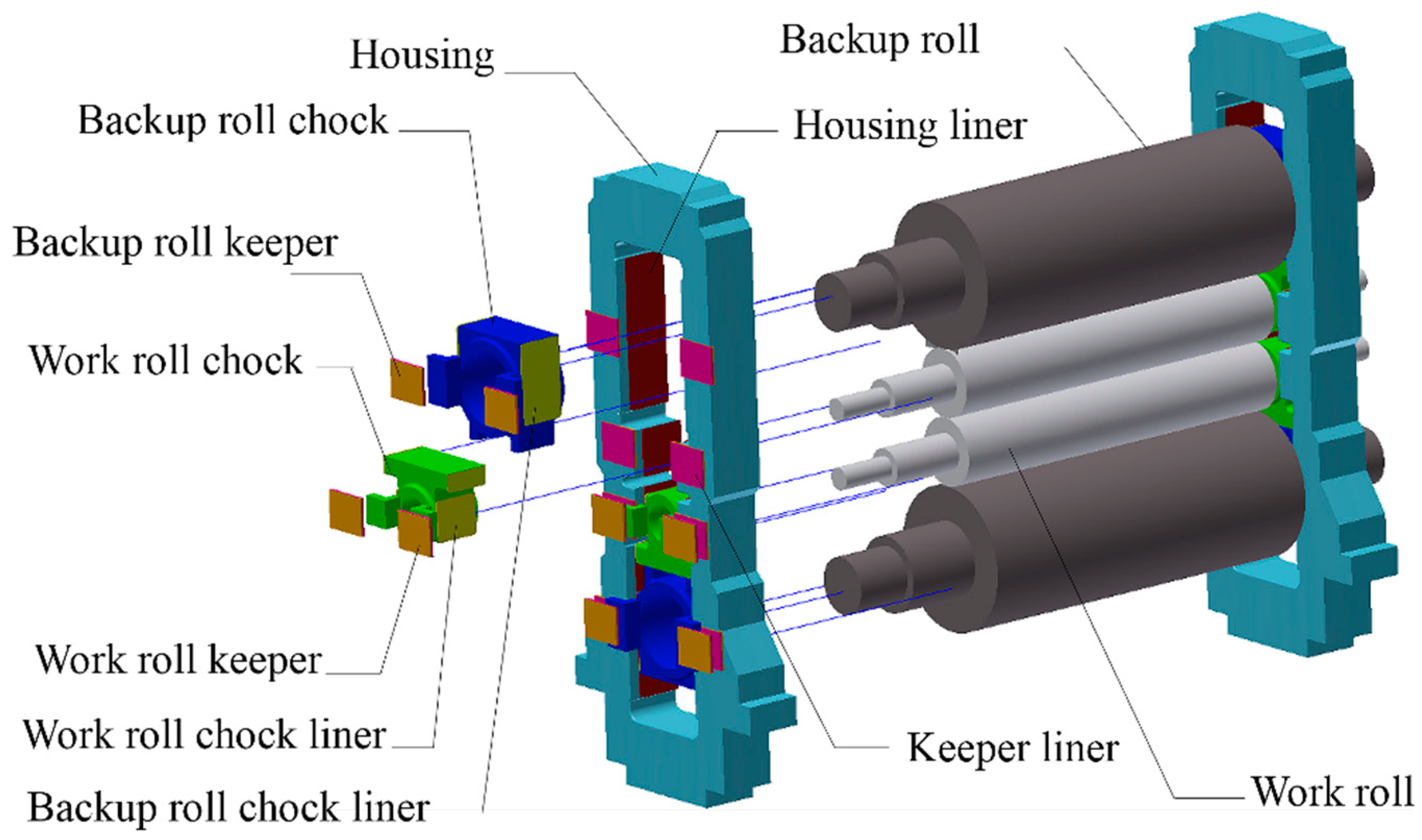

Introduction Roll chocks which accommodate the roll neck bearing for the mil rolls are sally steel casting designed to fit into the. We are catering to the requirement of Long Rolling Mills from 50000 TPY to 1 Million TPY on turnkey basis. Tendem or Continuous mills.

Provide rolling mill solutions including rolling passes design production line setup and workshop layout according to your requirements. The roll stand is the main part of the mill where the rolling process is actually done. The DRM mills in both powered and manual are our highest specification range of mills with no compromise on design quality or.

This article describes ma jor conceptual design steps from a given product mix to an optimal mill. The roller guide boxes have simple design which ensures durability standards easy installation and smooth operation in diverse rolling conditions. A rolling mill includes one or more roller stands a main drive motor reducing gear stand pinion flywheel and coupling gear between the units.

The rolling mill guides are manufactured using new technology and quality material. Eight optimization steps pass schedule generation work roll determination backup. The selection of the rolling mill pass system is an important part of the rolling mill pass design.

The rolls are supported in bearing housed in sturdy upright frames called stands which are grouted to the rolling mill floor. Cantilever compact mill stands are employed in a wide range of sizes for a vast variety of applications. In hot rolling mills for long products guide equipments guide the rolling stock at the The design of roller guides is based on rolling frictions and hence these SBQ3 BEST and H3 are the latest technologies applied to production processes for special bar quality special steel commercial steel bars and high-speed Unique design of roller.

One-way Vertical Looper Four-Way Chrome Vertical Looper 7-Way Vertical Looper. Four high rolling mills. Abuts against the guide with its ends lapped above and below show that it is not moved by any displacement of the.

These original concepts have been continuously developing to meet the market. Produce a Bend Progression or Flower. Connect with sellers directly.

Two High Rolling Mills. All our rolling mills are designed to last an extremely long time so picking the right one is key. Layout and design the Roll Forming Tooling around the flower.

This guide is designed to help your selection process and make sure you get the mill you need and want. A rolling mill guide for use in rod mills merchant mills and the like comprising a guide box two opposed blocks mounted in the guide box on opposite sides of the mill pass line and having longitudinally extending channels in their adjacent faces separate metal plates bridging the respective channels and shaped to flt closely against the. Rolling feasibility gage uniformity and strip marketability will be discussed to link.

Round sequence which results in less guide wear and simpler guide design. Rolling mill roll chock modeling design analysis and optimization. Design guide plates according to the request of customers.

Surplus Record established 1924. It contains two heavy rolls fixed one over the other. The rolls should have sufficient strength stiffness and good wear resistance.

Features of the Rolling Mill Guides Our mill guide has excellent features such as corrosive resistance unique design. You can select the mill guides which suits your rolling mills or original matched types. Ad Browse used roll mills on the leading machinery marketplace.

At the same time the hardness of the working surface of the roll is also one of the main quality indexes of the roll. It is basically consists of housings in which antifriction bearings are used for mounting the rolls are fitted. Middle Group Roller Roller Finishing Group Roller.

The rolls of rolling mill consist of three parts. Reconditioned roll mills listings updated daily. A rolling mill guide comprising two complemeiitary guide blocks adapted to engage a bar of stock on oppbsitesides as it travels longitudinally aling the siubstantially horizontal pass line of a rolling mill means supporting the blocks from beneath the same the center of gravity of each block being located outside the supported area of the.

We have experience from decades in design and supply of rolling mill equipment. Respect to the pass axis two rigid levers each of which is pivotally mounted on one of said pivot pins two. Static runner 2 - 4 Bench Roller Slide 4 Reel Entry Stations Custom Design House Slit Cutting Boxes Pipe Type Guide Case Roller Shelves Double Row Entry Cabinets.

The design of course may advantageously be applied not only to horizontal frames but to vertical frames as well. Preferred fields of application are namely i single strand mill lines in horizontalvertical arrangement ii. Mill guides are to help billet safely pass through rolling mill.

Rolling Mill Guide Rollers. What is claimed is.

Ebay Sponsored Manual Rolling Mill Machine 85mm Wire Flat Pattern Sheet Metal Jewelry Tool Us Rolling Mill Jewelry Tools Patterned Sheets

Metals Free Full Text Effect Of Clearances In Mill Stands On Strip End Motion During Finishing Rolling Html

Rolling Mills Industrial Efficiency Technology Measures

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Rolling Mill Guides Morgardshammar

0 comments

Post a Comment